Suzhou Volsun Electronics Technology Co., Ltd.

Views: 0 Author: Site Editor Publish Time: 2025-12-08 Origin: Site

Modern electrical systems are under constant pressure, running at higher temperatures and facing greater mechanical stress. Wires are subjected to heat, vibration, and voltage fluctuations, making them vulnerable to failure. Fiberglass Sleeving plays a crucial role in mitigating these issues by providing a protective layer that shields cables from environmental factors such as heat, abrasion, and chemical exposure. This guide offers comprehensive insights on how to select the right sleeving based on temperature ratings, coating types, and application needs. You'll also learn how to properly size and compare different sleeving options to ensure long-term safety and reliability in electrical systems, ultimately extending their lifespan and improving performance.

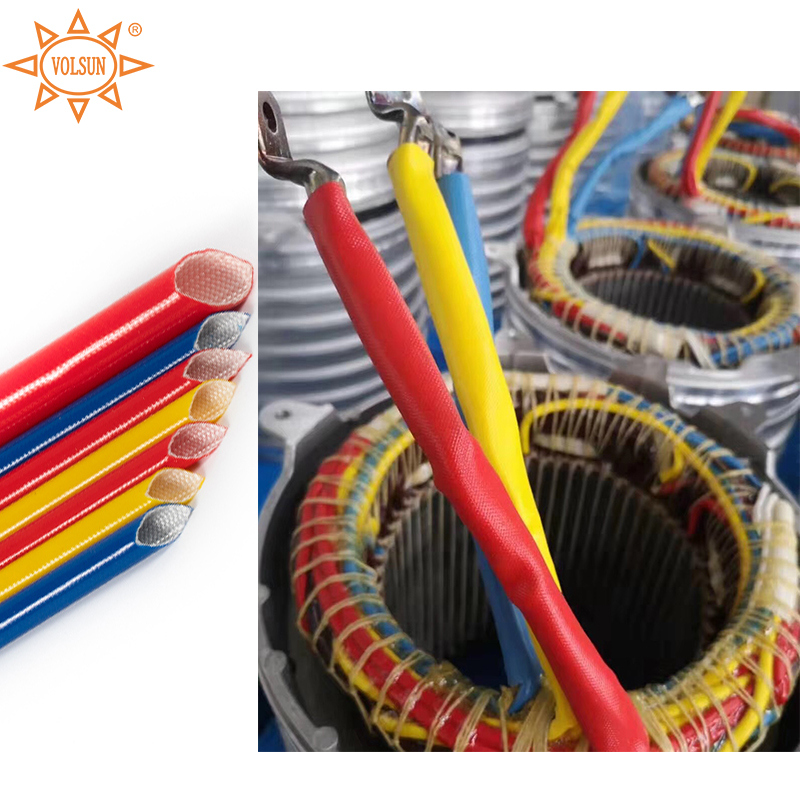

Fiberglass sleeving is constructed by braiding fiberglass yarns into a flexible, durable tube that provides robust protection for wires and cables. The braided structure helps maintain its shape during bending, ensuring consistent coverage. It also offers stable dielectric insulation, making it ideal for high-temperature and high-voltage applications.

Fiberglass sleeving may be uncoated or coated depending on application needs.

Category | Uncoated Fiberglass Sleeving | Coated Fiberglass Sleeving |

Heat Resistance | Highest; suitable for extreme temperatures | Lower; depends on coating (e.g., silicone ~200°C) |

Environmental Protection | Limited oil and chemical resistance | Strong oil, fuel, and solvent resistance (PVC/Silicone) |

Mechanical Durability | Moderate abrasion protection | Enhanced abrasion performance (Acrylic/PUR) |

Flexibility | Can stiffen under high heat | Often more flexible, especially silicone-coated |

Best Use Cases | Furnaces, high-temp coils, Class-H motors | Automotive, transformers, industrial equipment |

Fiberglass sleeving prevents electrical failure by forming a durable barrier around conductors. It reduces arcing, protects wires from sharp edges, and minimizes damage from oil, dust, and moisture. Its braided structure also slows heat transfer, helping insulation stay stable under continuous thermal stress. These combined protective effects keep wiring reliable in demanding electrical and industrial environments.

Fiberglass sleeving handles roughly 155°C to 500°C, depending on the coating and construction. Uncoated types offer the highest heat tolerance, while silicone-coated versions perform reliably near 200°C. Acrylic coatings suit mid-temperature needs, allowing engineers to match sleeving to specific thermal and mechanical requirements.

Feature | Fiberglass Sleeving | Heat-Shrink | Rubber Tubing | Plastic Conduit |

Heat resistance | ★★★★★ | ★★☆☆☆ | ★★★☆☆ | ★★☆☆☆ |

Flexibility | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ | ★☆☆☆☆ |

Abrasion protection | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ |

Dielectric strength | High | Medium | Medium | Low |

Rework ability | Easy | Hard | Medium | Hard |

Uncoated fiberglass sleeving provides exceptional heat resistance, making it the ideal choice for high-temperature environments such as heaters, furnaces, and Class-H motor windings. Its ability to maintain stable insulation under intense heat ensures reliable performance in extreme conditions. With minimal chemical exposure, this sleeving offers long-lasting protection against thermal degradation, making it suitable for applications where maintaining electrical safety and insulation integrity is critical.

Silicone coating enhances flexibility and dielectric strength, making it ideal for applications like motors, transformers, and electronic assemblies. This sleeving offers reliable heat resistance, preventing insulation breakdown under high temperatures while ensuring smooth installation and long-term protection. It is perfect for environments where both electrical performance and flexibility are crucial.

Acrylic-coated fiberglass sleeving offers strong abrasion resistance, providing added durability in mechanical environments. It maintains dimensional stability in moderate-temperature applications, ensuring reliable protection where extreme heat is not a concern. This sleeving is particularly suited for systems requiring robust mechanical performance without compromising insulation integrity.

PUR-coated fiberglass sleeving excels in high-wear environments, offering superior resistance to abrasion and mechanical stress. It is ideal for machinery, automation equipment, and dynamic cable systems subject to continuous vibration. The PUR coating enhances the sleeving’s longevity, protecting the wiring from external damage while maintaining insulation performance.

Uncoated fiberglass offers the highest heat tolerance, making it ideal for extreme environments. Silicone-coated fiberglass provides reliable insulation up to 200°C, offering flexibility and thermal protection in high-heat conditions. Acrylic-coated fiberglass is suitable for moderate temperatures, balancing cost and durability. Choosing the right thermal class ensures optimal insulation performance and longevity in various electrical applications, preventing insulation failure and enhancing system safety.

The insulation or dielectric strength of fiberglass sleeving is crucial for ensuring electrical safety and preventing arcing. Typical voltage ratings include 1500V, 2500V, 4000V, and 7000V, with higher ratings needed for more demanding applications. Selecting the appropriate dielectric strength ensures reliable performance in high-voltage systems, preventing insulation failure and ensuring long-term protection.

For systems exposed to oil or chemicals, it’s essential to choose coated fiberglass sleeving that meets JIS C 2320 testing standards. This ensures the sleeving can withstand prolonged exposure to fuels, lubricants, and industrial solvents without degrading. Coatings such as PVC or silicone enhance the sleeving’s resistance to harsh chemicals, protecting the wiring and ensuring reliable electrical insulation in demanding environments. This added protection extends the service life of electrical components.

In applications where vibration or frequent cable movement occurs, PUR and acrylic-coated fiberglass sleeving offer superior abrasion protection. These coatings are more effective than silicone or uncoated fiberglass in high-friction environments. The added resistance extends the sleeving's service life, preventing wear and tear that could compromise the insulation, ensuring consistent performance even in demanding industrial or mechanical settings.

Silicone-coated fiberglass sleeving provides exceptional flexibility, allowing for easy installation in tight or complex routing paths. It maintains its shape and flexibility even under high temperatures. In contrast, uncoated fiberglass can become stiff and less flexible when exposed to heat, which may cause challenges in installation and negatively affect the long-term durability of cables in high-heat environments.

Fiberglass sleeving that complies with UL, JIS, and RoHS standards ensures reliable electrical insulation, safety, and environmental protection. UL certification guarantees safety and performance, JIS ensures high standards in Japan, and RoHS compliance confirms that the product is free from harmful substances. These certifications make the sleeving suitable for industrial, automotive, and consumer applications while meeting strict regulatory and environmental requirements.

Accurate measurement of the outer diameter (OD) using calipers ensures the Fiberglass Sleeving fits properly, preventing overstretching. A correct fit maintains the braid's protective properties, ensuring stable insulation, preventing wire damage, and supporting long-term reliability in electrical systems. Proper sizing is essential for both mechanical stability and electrical performance.

Selecting Fiberglass Sleeving with an inside diameter slightly larger than the cable ensures easy installation. Sleeves that are too loose can slip off, while too-tight sleeves distort the braid, weakening insulation and compromising the mechanical and electrical stability of the sleeving, reducing long-term durability.

Fiberglass sleeving expands when compressed, making installation easier over connectors or bundles. However, overstretching the braid can weaken its dielectric strength and mechanical durability, reducing its ability to withstand thermal or mechanical stress over time and compromising long-term performance in demanding applications.

For a smooth, professional installation, use a hot knife to seal Fiberglass Sleeving ends, preventing fraying. Secure the ends with clamps or heat-shrink tubing and avoid sharp bends. This ensures the sleeving maintains its structural integrity, electrical insulation, and performance, guaranteeing optimal system operation over time.

Fiberglass sleeving effectively protects winding leads from heat, vibration, and oil exposure, ensuring stable insulation. This makes it ideal for use in rotating machinery and transformer applications that experience continuous thermal stress, preventing insulation breakdown and maintaining electrical performance in demanding environments.

Coated fiberglass sleeving provides exceptional protection against oils, fuels, vibration, and rapid heat cycles. This makes it perfect for automotive wiring, EV systems, and components exposed to mechanical wear and harsh chemical conditions, ensuring long-lasting insulation and reliable electrical protection.

The braided structure of fiberglass sleeving withstands constant vibration and mechanical loads, providing reliable insulation for avionics wiring, control circuits, and aerospace harnesses. This ensures stable electrical performance in high-stress environments, even under the most demanding conditions encountered in aerospace applications.

Fiberglass sleeving is designed to endure thermal cycling and abrasion, protecting control wiring in ovens, heaters, industrial machinery, and high-temperature electrical enclosures. It ensures long-term insulation stability, preventing breakdowns and maintaining electrical integrity in industrial environments subject to frequent temperature changes.

Fiberglass sleeving with high dielectric ratings is essential for high-voltage systems, such as EV battery packs, inverter circuits, and power conversion equipment. It ensures consistent insulation performance, providing protection against voltage stress and ensuring the reliable operation of electrical systems in high-voltage applications.

When handling fiberglass sleeving, wear gloves, goggles, and long sleeves to avoid irritation from glass fibers. Use a hot knife to seal the edges and prevent fraying. Always keep the sleeving dry and clean, and install it only when the equipment has completely cooled to ensure safe and effective insulation.

Brittleness often signals that the sleeving has exceeded its rated temperature, causing the coating to crack or harden. This typically occurs in high-heat environments. To prevent thermal degradation and protect your system, select a higher-temperature rated sleeving or opt for uncoated fiberglass, which provides superior heat resistance and remains durable under extreme conditions, ensuring long-term insulation stability.

Slippage happens when the inside diameter is too large or the sleeving isn’t securely fastened. This can lead to unreliable protection. To prevent this, measure the cable's outer diameter accurately and select a Fiberglass Sleeving with a slightly larger inside diameter. Use clamps or heat-shrink tubing to secure the ends, maintaining consistent protection and insulation.

Insulation failure is typically caused by insufficient dielectric strength or poor chemical resistance. To avoid this, make sure the sleeving's voltage class and oil-resistance rating match the system’s environmental conditions. This ensures it can withstand electrical, mechanical, and chemical stresses without breaking down, maintaining reliable performance in demanding applications.

In environments with constant vibration, the sleeving surface can wear down, especially if the coating is too soft. To extend the life of the sleeving, consider switching to PUR-coated fiberglass, which offers superior abrasion resistance. This helps protect against wear, ensuring the sleeving remains effective even in machinery and dynamic systems exposed to frequent mechanical movement.

Modern systems face heat and vibration.Fiberglass Sleeving offers stable protection.It improves safety in demanding equipment. Suzhou Volsun Electronics Technology Co., Ltd. provides reliable products that enhance insulation performance and support long-term system durability.

A: Fiberglass Sleeving protects wires from heat and abrasion and is widely used in motors and transformers as a durable form of cable sleeving.

A: Fiberglass Sleeving offers strong insulation and heat resistance, helping prevent arcing and failure in demanding cable sleeving environments.

A: Coated Fiberglass Sleeving provides improved abrasion resistance and is ideal for vibrating machinery where cable sleeving needs added durability.

A: Measure the wire’s outer diameter and select Fiberglass Sleeving slightly larger to ensure proper fit and reliable cable sleeving performance.

What is the difference between graphite and silicone thermal pads?

Volson Highlights Innovative EV Material Solutions at Global xEV Drive Conference

How Busbar Heat Shrink Tubing Protects Medium And Low Voltage Power Systems

How Effectively Solve The Problem of Electrocorrosion in Motor Bearings?

An Application Case of Silicone Fiberglass Sleeving in Fireproof Sealing