Suzhou Volsun Electronics Technology Co., Ltd.

Views: 0 Author: Site Editor Publish Time: 2026-01-31 Origin: Site

Have you ever wondered how electronic devices stay protected in harsh environments? Silicone potting compound plays a vital role in safeguarding sensitive components from moisture, dust, and temperature extremes. In this article, we will explore the benefits of silicone potting compound, its applications, and why it is essential for ensuring the longevity and reliability of electronic devices.

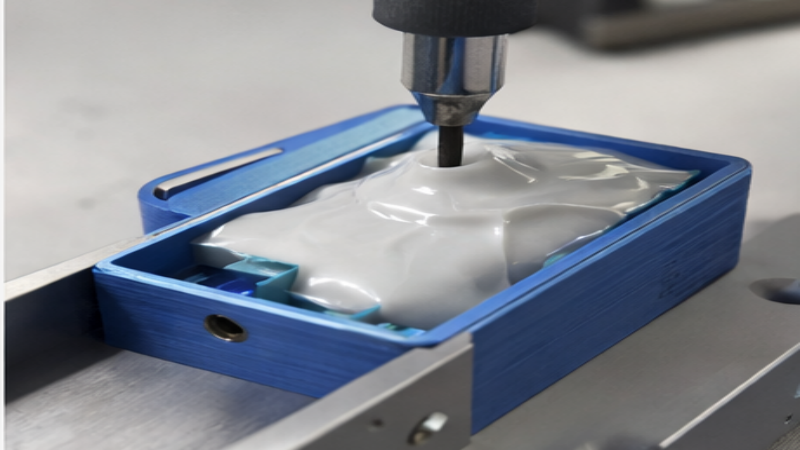

Silicone potting compound is a highly flexible and durable material used primarily in the electronics industry to protect sensitive components from environmental damage. This compound is applied to electronic devices as a protective encapsulant, forming a solid yet flexible barrier. It shields components from harsh conditions, such as moisture, dust, vibration, and extreme temperatures, ensuring the longevity and reliability of the devices.

Silicone potting compounds are made of silicone polymers combined with various additives to enhance their properties, such as thermal conductivity and electrical insulation. These compounds come in two main systems:

1. One-Part Systems: Ready-to-use mixtures that cure upon exposure to heat or moisture.

2. Two-Part Systems: Require mixing before use and cure at room temperature or under heat.

The primary role of silicone potting compound in electronics is to provide a robust protective barrier. By encapsulating sensitive components like circuit boards, sensors, and power modules, it prevents damage caused by environmental factors such as moisture, contaminants, and mechanical stress.

Silicone potting compounds cure through either moisture activation or heat catalysis. Here’s how each system works:

● One-Part Systems: Cure when exposed to heat or humidity, forming a solid, rubber-like material.

● Two-Part Systems: Require mixing the resin and curing agent before application, and they cure at room temperature or with heat.

Once cured, silicone forms a resilient, stable barrier around the components, ensuring protection against environmental stressors. The flexibility of the silicone material also allows it to accommodate temperature-induced expansion and contraction without compromising the integrity of the device.

Silicone potting compounds are renowned for their exceptional thermal stability, which allows them to perform reliably in extreme temperature environments. They can withstand temperature fluctuations ranging from -60°C to 200°C, making them suitable for use in applications such as electronics, automotive, and aerospace. This wide thermal range ensures that components remain protected, even under harsh operating conditions.

Additionally, silicone potting compounds help dissipate heat generated by electronic components. With thermal conductivity ranging from 0.1-2.0W/m·K, the compound prevents overheating, thus improving the efficiency and lifespan of sensitive components.

The electrical insulation properties of silicone potting compounds are critical in safeguarding electronic circuits. With a high resistivity of ≥1×10¹³Ω·cm, these compounds act as a barrier, preventing electrical interference and short circuits. This feature is especially valuable for high-voltage applications, where any disruption in insulation could result in significant damage.

By encapsulating components like circuit boards, sensors, and power modules, silicone potting compounds provide an extra layer of protection against electrical faults, ensuring smooth and reliable operation of devices.

Unlike rigid materials like epoxy, silicone potting compounds remain flexible after curing, offering superior protection against mechanical stresses. Their rubber-like consistency allows them to absorb vibrations, shocks, and thermal expansion, which are common in environments subject to constant movement or temperature changes.

This flexibility makes silicone potting compounds ideal for a variety of applications, from automotive electronics to industrial machinery, ensuring that protected components are shielded from potential damage caused by physical impacts or environmental fluctuations.

Silicone potting compounds provide excellent moisture resistance, creating a waterproof seal around electronic components. This feature is vital for protecting devices in environments where moisture exposure is common, such as outdoor electronics or automotive systems. The compound prevents corrosion and ensures that sensitive components remain functional and free from damage caused by water or humidity.

In addition to moisture resistance, silicone potting compounds offer protection against dust, UV radiation, ozone, and various chemicals, further enhancing their suitability for use in harsh environmental conditions. Whether used in solar panels, wind turbines, or industrial electronics, silicone potting compounds ensure that electronic devices can endure challenging conditions while maintaining their performance and longevity.

Property | Description |

Thermal Stability | Can withstand temperatures from -60°C to 200°C, ensuring reliability in extreme conditions. |

Electrical Insulation | High resistivity (≥1×10¹³Ω·cm), protecting circuits from interference and short circuits. |

Flexibility | Retains flexibility after curing, absorbing mechanical stresses from vibrations and thermal expansion. |

Moisture Resistance | Forms a waterproof seal, protecting components from moisture, dust, and corrosion. |

Environmental Protection | Resistant to UV radiation, ozone, and various chemicals, ensuring durability in harsh environments. |

Silicone potting compounds are vital for protecting sensitive electronic components such as circuit boards, sensors, and connectors. They create a durable protective layer that shields electronics from moisture, dust, and temperature extremes. This encapsulation ensures the longevity and performance of the components, particularly in environments where traditional protective coatings might not be sufficient. Silicone potting compounds help maintain functionality, reducing the risk of component failure and improving overall device reliability.

In the automotive sector, silicone potting compounds are essential for safeguarding electronic components that are exposed to extreme conditions. Components like engine control units (ECUs), sensors, and connectors often face high temperatures, vibrations, and varying weather. Silicone potting compounds provide effective protection against these stresses, preventing damage from moisture and mechanical shocks. This protection ensures the longevity and reliability of automotive electronics, even in the toughest environments, from engine bays to harsh outdoor conditions.

Silicone potting compounds are extensively used in aerospace and defense applications due to their ability to withstand extreme environments. They are crucial for protecting avionics, navigation systems, and other electronic components in aircraft and defense systems. With their resistance to temperature fluctuations, vibrations, and exposure to environmental contaminants, silicone potting compounds ensure that these systems operate reliably. Their moisture resistance and mechanical stability are particularly important for systems that operate at high altitudes or in space, where failure can have serious consequences.

Silicone potting compounds are widely used in the LED lighting industry, particularly for outdoor applications like streetlights and tunnel lights. By encapsulating LEDs and other components, these compounds provide protection against moisture, dust, and mechanical stress, all while maintaining optical clarity. The potting compound helps extend the lifespan of the LEDs, preventing degradation from environmental exposure. This makes silicone potting compounds an ideal choice for ensuring that outdoor lighting systems perform reliably over time, even under challenging weather conditions.

In the renewable energy sector, silicone potting compounds are used to protect electrical components in solar panels, wind turbines, and other energy systems. The compound’s ability to form a waterproof seal and resist environmental contaminants ensures the longevity of these systems. In solar panels, for example, silicone potting protects power modules from moisture, dust, and temperature fluctuations, improving efficiency and lifespan. Similarly, silicone potting compounds are crucial for wind turbines, where they shield components from UV radiation, moisture, and harsh environmental conditions.

Application Area | Key Benefits of Silicone Potting Compound |

Electronics | Shields from moisture, dust, and temperature extremes, enhancing reliability. |

Automotive | Protects ECUs and sensors from heat, vibrations, and moisture in extreme environments. |

Aerospace & Defense | Ensures the reliable operation of avionics and navigation systems under harsh conditions. |

LED Lighting | Provides moisture resistance and mechanical protection for long-lasting, reliable performance. |

Renewable Energy | Protects solar panels and wind turbines from environmental damage, ensuring efficiency and longevity. |

Silicone potting compounds significantly enhance the lifespan of electronic components. By forming a protective barrier against harmful elements like moisture, dust, and temperature extremes, they help prevent the degradation of sensitive parts. This protection ensures that devices perform reliably over an extended period, reducing maintenance and replacement costs. In high-demand sectors like automotive electronics and renewable energy, silicone potting compounds help ensure the long-term functionality and durability of critical components.

One of the standout benefits of silicone potting compounds is their superior environmental protection. They create a waterproof seal around components, protecting them from moisture and humidity. Beyond moisture protection, silicone potting compounds are also resistant to UV radiation, ozone, and many chemicals. This makes them ideal for outdoor applications such as solar panels and industrial electronics, where exposure to the elements is common. By ensuring environmental resilience, silicone potting compounds help devices continue to function optimally in harsh conditions.

Silicone potting compounds provide essential mechanical protection by absorbing shock and vibrations that could damage sensitive electronic components. Their flexibility helps reduce the stress on parts that may otherwise be subject to mechanical impacts. This is especially important in industries like automotive and aerospace, where components experience constant vibrations and physical stresses. Silicone potting compounds protect against these forces, ensuring the longevity and reliability of devices in high-vibration environments.

Silicone potting compounds are highly versatile and can be customized for a wide range of applications. Manufacturers can modify the formulation to enhance specific properties, such as thermal conductivity, electrical insulation, or flexibility. This adaptability makes silicone potting compounds ideal for use in diverse industries like consumer electronics, automotive systems, and renewable energy.

When selecting a silicone potting compound, it's crucial to consider the environmental conditions that the protected components will face. Silicone compounds are particularly well-suited for harsh environments due to their excellent resistance to temperature extremes, moisture, and UV exposure.

● Temperature Extremes: Silicone potting compounds can withstand temperatures ranging from -60°C to 200°C, making them ideal for both high-heat and low-temperature applications.

● Moisture Resistance: These compounds are water-resistant, offering protection against humidity, condensation, and even direct water exposure.

● UV Exposure: Silicone potting compounds resist degradation from UV radiation, which is essential for outdoor applications like solar panels and outdoor sensors.

By choosing a compound that meets the specific environmental needs of your application, you ensure optimal protection and reliability for your components.

Next, it's important to assess the electrical and mechanical needs of the components you're protecting. Silicone potting compounds offer a range of properties that make them ideal for various applications:

● Electrical Insulation: Silicone provides high resistivity and excellent dielectric properties, protecting sensitive electronics from electrical interference, short circuits, and failures.

● Mechanical Protection: The flexibility of silicone allows it to absorb vibrations, shocks, and thermal expansion, making it ideal for components exposed to mechanical stress or environmental fluctuations. This is particularly important in industries like automotive and aerospace.

The method of application also plays a crucial role in selecting the right silicone potting compound. Two main systems are available:

1. One-Part Systems: These are ready-to-use mixtures that cure upon exposure to heat or moisture. They are ideal for applications that require ease of use and quick processing.

2. Two-Part Systems: These require mixing before application and allow for greater control over curing time and consistency. This option is preferred for more specialized applications where specific curing conditions are needed.

Silicone potting compounds are crucial for protecting electronic components from environmental damage. They offer benefits such as thermal stability, electrical insulation, and moisture resistance. As industries increasingly rely on these materials, the demand continues to grow. Suzhou Volsun Electronics Technology Co., Ltd. provides high-performance silicone potting compounds, offering tailored solutions for a variety of applications, ensuring the reliability and longevity of electronic devices.

A: Silicone potting compound is used to protect electronic components from environmental damage, including moisture, dust, and extreme temperatures. It is widely applied in industries such as automotive, aerospace, and renewable energy to enhance the reliability and longevity of sensitive electronics.

A: Silicone potting compound offers excellent thermal stability, withstanding temperatures from -60°C to 200°C. Its flexibility and resistance to temperature fluctuations make it ideal for high-performance applications in harsh environments.

A: Silicone potting compound provides superior flexibility, electrical insulation, and moisture resistance, making it ideal for protecting sensitive electronics. It also offers better long-term durability and is resistant to UV exposure, chemicals, and mechanical stress.

A: While silicone potting compound can be more expensive than other materials like epoxy, its long lifespan, superior protection, and lower maintenance requirements justify the investment, especially in high-performance and high-reliability applications.