Suzhou Volsun Electronics Technology Co., Ltd.

| Availability: | |

|---|---|

| Quantity: | |

TZRS-PTFE260(1.7X)(4X)

Volsun

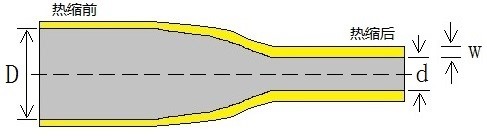

Standard Heat Shrink Tube is a cost-effective, cross-linked polyolefin tubing designed to provide insulation, strain relief, and abrasion resistance for electrical and mechanical components. When heated, it shrinks uniformly at a 3:1 ratio, conforming tightly to the substrate to create a durable, tamper-proof layer. Operating within a temperature range of -55°C to 135°C, it is a versatile solution for residential, commercial, and light industrial applications. Available in an array of colors and diameters, this tubing simplifies wire identification and organization while meeting global safety certifications like UL 224 and CSA C22.2. Its balance of performance and affordability makes it a staple in electronics, automotive repair, and DIY projects.

1. User-Friendly Activation: Contracts rapidly at 90°C–120°C using a heat gun, oven, or even a controlled open flame, ensuring quick deployment in field repairs.

2. Enhanced Safety: Flame-retardant additives reduce fire risks, while smooth edges prevent wire damage during installation.

3. Multi-Purpose Protection: Guards against moisture, dust, and minor mechanical impacts, extending the lifespan of household appliances and low-voltage circuits.

4. Color Customization: Offered in over 10 standard colors (e.g., yellow, green, transparent) for effortless circuit tracing and compliance with international wiring codes.

5. Cost Efficiency: Reduces maintenance costs by up to 30% through reliable insulation and reduced downtime.

6. Flexible Sizing: Available in diameters from 1mm to 50mm, with custom-cut lengths to minimize material waste.

Standard Heat Shrink Tubes are ubiquitous in everyday and industrial settings:

· Consumer Electronics: Insulating USB cables, headphone jacks, and power adapters in smartphones, laptops, and gaming devices.

· Automotive Wiring: Bundling engine control unit (ECU) harnesses, protecting battery lugs, and color-coding trailer light connections.

· Building Electrification: Securing terminal blocks, circuit breakers, and LED lighting systems in residential and commercial buildings.

· HVAC Systems: Sealing thermostat wires and refrigerant line sensors against condensation and temperature extremes.

· Marine Electronics: Waterproofing fishfinders, bilge pump switches, and navigation light connections on boats and yachts.

· Agricultural Machinery: Shielding irrigation system controls and tractor wiring from mud, fertilizer, and rodent damage.

Item | Typical Data | Test Method |

Tensile strength | 2000 psi | ASTM D638 |

Elongation at break | ≥200% | ASTM D638 |

Flame retardancy | V0 | UL224 |

Breakdown strength | ≥26kV/mm | ASTM D876 |

Water absorption | <0.1% | ASTM D 570 |

Copper corrosion | pass | UL224 |

Size | Supplied I.D. (mm) | After fully recovery(mm) | Standard packing (M/Roll) | ||

Inner diameter | Wall thickness | ||||

Φ0.5 | 0.5±0.2 | ≤0.40 | 0.15±0.05 | 200 | |

Φ1.0 | 1.0±0.2 | ≤0.60 | 0.15±0.05 | 200 | |

Φ1.5 | 1.5±0.2 | ≤0.90 | 0.15±0.05 | 200 | |

Φ2.0 | 2.0±0.2 | ≤1.20 | 0.15±0.05 | 200 | |

Φ2.5 | 2.5±0.3 | ≤1.50 | 0.15±0.05 | 200 | |

Φ3.0 | 3.0±0.3 | ≤1.80 | 0.20±0.05 | 200 | |

Φ3.5 | 3.5±0.3 | ≤2.10 | 0.20±0.05 | 100 | |

Φ4.0 | 4.0±0.3 | ≤2.40 | 0.20±0.05 | 100 | |

Φ4.5 | 4.5±0.3 | ≤2.70 | 0.20±0.05 | 100 | |

Φ5.0 | 5.0±0.3 | ≤3.10 | 0.20±0.05 | 100 | |

Φ5.5 | 5.5+0.5 -0.2 | ≤3.30 | 0.20±0.05 | 100 | |

Φ6.0 | 6.0+0.5 -0.2 | ≤3.60 | 0.25±0.05 | 100 | |

Φ6.5 | 6.5+0.5 -0.2 | ≤3.80 | 0.25±0.05 | 100 | |

Φ7.0 | 7.0+0.5 -0.2 | ≤4.20 | 0.25±0.05 | 100 | |

Φ7.5 | 7.5+0.5 -0.2 | ≤4.50 | 0.25±0.05 | 100 | |

Φ8.0 | 8.0+0.8 -0.2 | ≤4.80 | 0.25±0.05 | 100 | |

Φ8.5 | 8.5+0.8 -0.2 | ≤5.00 | 0.25±0.05 | 100 | |

Φ9.0 | 9.0+0.8 -0.2 | ≤5.30 | 0.25±0.05 | 100 | |

Φ9.5 | 9.5+0.8 -0.2 | ≤5.60 | 0.25±0.05 | 100 | |

Φ10.0 | 10.0+0.8 -0.2 | ≤5.90 | 0.25±0.05 | 100 | |

Φ11.0 | 11.0+0.8 -0.2 | ≤6.50 | 0.25±0.05 | 100 | |

Φ12.0 | 12.0+0.8 -0.2 | ≤7.10 | 0.25±0.05 | 100 | |

Φ13.0 | 13.0+0.8 -0.2 | ≤7.70 | 0.25±0.05 | 100 | |

Φ14.0 | 14.0+0.8 -0.2 | ≤8.30 | 0.25±0.05 | 100 | |

Φ15.0 | 15.0+0.8 -0.2 | ≤8.80 | 0.25±0.05 | 100 | |

Φ16.0 | 16.0+0.8 -0.2 | ≤9.50 | 0.25±0.05 | 100 | |

Size | Supplied I.D. (mm) | After fully recovery (mm) | Standard packing (M/Roll) | ||

Inner diameter | Wall thickness | ||||

Φ2.0 | 2.0+0.8 -0.2 | ≤0.50 | 0.25±0.05 | 200 | |

Φ2.5 | 2.5+0.8 -0.2 | ≤0.60 | 0.25±0.05 | 200 | |

Φ3.0 | 3.0+0.8 -0.2 | ≤0.80 | 0.25±0.05 | 100 | |

Φ4.0 | 4.0+0.8 -0.2 | ≤1.00 | 0.30±0.05 | 100 | |

Φ4.5 | 4.5+0.8 -0.2 | ≤1.20 | 0.30±0.05 | 100 | |

Φ5.0 | 5.0+0.8 -0.2 | ≤1.30 | 0.30±0.05 | 100 | |

Φ6.0 | 6.0+0.8 -0.2 | ≤1.50 | 0.30±0.05 | 100 | |

Φ7.0 | 7.0+0.8 -0.2 | ≤1.80 | 0.30±0.05 | 100 | |

Φ8.0 | 8.0+1.0 -0.2 | ≤2.20 | 0.30±0.05 | 100 | |

Φ9.0 | 9.0+1.0 -0.2 | ≤2.40 | 0.30±0.05 | 100 | |

Φ10.0 | 10.0+1.5 -0.5 | ≤2.70 | 0.30±0.05 | 100 | |

Φ11.0 | 11.0+1.5 -0.5 | ≤2.90 | 0.30±0.05 | 100 | |

Φ12.0 | 12.0+1.5 -0.5 | ≤3.20 | 0.30±0.05 | 100 | |

Note: Special size and packaging can be customized upon request.

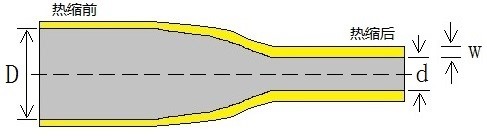

Standard Heat Shrink Tube is a cost-effective, cross-linked polyolefin tubing designed to provide insulation, strain relief, and abrasion resistance for electrical and mechanical components. When heated, it shrinks uniformly at a 3:1 ratio, conforming tightly to the substrate to create a durable, tamper-proof layer. Operating within a temperature range of -55°C to 135°C, it is a versatile solution for residential, commercial, and light industrial applications. Available in an array of colors and diameters, this tubing simplifies wire identification and organization while meeting global safety certifications like UL 224 and CSA C22.2. Its balance of performance and affordability makes it a staple in electronics, automotive repair, and DIY projects.

1. User-Friendly Activation: Contracts rapidly at 90°C–120°C using a heat gun, oven, or even a controlled open flame, ensuring quick deployment in field repairs.

2. Enhanced Safety: Flame-retardant additives reduce fire risks, while smooth edges prevent wire damage during installation.

3. Multi-Purpose Protection: Guards against moisture, dust, and minor mechanical impacts, extending the lifespan of household appliances and low-voltage circuits.

4. Color Customization: Offered in over 10 standard colors (e.g., yellow, green, transparent) for effortless circuit tracing and compliance with international wiring codes.

5. Cost Efficiency: Reduces maintenance costs by up to 30% through reliable insulation and reduced downtime.

6. Flexible Sizing: Available in diameters from 1mm to 50mm, with custom-cut lengths to minimize material waste.

Standard Heat Shrink Tubes are ubiquitous in everyday and industrial settings:

· Consumer Electronics: Insulating USB cables, headphone jacks, and power adapters in smartphones, laptops, and gaming devices.

· Automotive Wiring: Bundling engine control unit (ECU) harnesses, protecting battery lugs, and color-coding trailer light connections.

· Building Electrification: Securing terminal blocks, circuit breakers, and LED lighting systems in residential and commercial buildings.

· HVAC Systems: Sealing thermostat wires and refrigerant line sensors against condensation and temperature extremes.

· Marine Electronics: Waterproofing fishfinders, bilge pump switches, and navigation light connections on boats and yachts.

· Agricultural Machinery: Shielding irrigation system controls and tractor wiring from mud, fertilizer, and rodent damage.

Item | Typical Data | Test Method |

Tensile strength | 2000 psi | ASTM D638 |

Elongation at break | ≥200% | ASTM D638 |

Flame retardancy | V0 | UL224 |

Breakdown strength | ≥26kV/mm | ASTM D876 |

Water absorption | <0.1% | ASTM D 570 |

Copper corrosion | pass | UL224 |

Size | Supplied I.D. (mm) | After fully recovery(mm) | Standard packing (M/Roll) | ||

Inner diameter | Wall thickness | ||||

Φ0.5 | 0.5±0.2 | ≤0.40 | 0.15±0.05 | 200 | |

Φ1.0 | 1.0±0.2 | ≤0.60 | 0.15±0.05 | 200 | |

Φ1.5 | 1.5±0.2 | ≤0.90 | 0.15±0.05 | 200 | |

Φ2.0 | 2.0±0.2 | ≤1.20 | 0.15±0.05 | 200 | |

Φ2.5 | 2.5±0.3 | ≤1.50 | 0.15±0.05 | 200 | |

Φ3.0 | 3.0±0.3 | ≤1.80 | 0.20±0.05 | 200 | |

Φ3.5 | 3.5±0.3 | ≤2.10 | 0.20±0.05 | 100 | |

Φ4.0 | 4.0±0.3 | ≤2.40 | 0.20±0.05 | 100 | |

Φ4.5 | 4.5±0.3 | ≤2.70 | 0.20±0.05 | 100 | |

Φ5.0 | 5.0±0.3 | ≤3.10 | 0.20±0.05 | 100 | |

Φ5.5 | 5.5+0.5 -0.2 | ≤3.30 | 0.20±0.05 | 100 | |

Φ6.0 | 6.0+0.5 -0.2 | ≤3.60 | 0.25±0.05 | 100 | |

Φ6.5 | 6.5+0.5 -0.2 | ≤3.80 | 0.25±0.05 | 100 | |

Φ7.0 | 7.0+0.5 -0.2 | ≤4.20 | 0.25±0.05 | 100 | |

Φ7.5 | 7.5+0.5 -0.2 | ≤4.50 | 0.25±0.05 | 100 | |

Φ8.0 | 8.0+0.8 -0.2 | ≤4.80 | 0.25±0.05 | 100 | |

Φ8.5 | 8.5+0.8 -0.2 | ≤5.00 | 0.25±0.05 | 100 | |

Φ9.0 | 9.0+0.8 -0.2 | ≤5.30 | 0.25±0.05 | 100 | |

Φ9.5 | 9.5+0.8 -0.2 | ≤5.60 | 0.25±0.05 | 100 | |

Φ10.0 | 10.0+0.8 -0.2 | ≤5.90 | 0.25±0.05 | 100 | |

Φ11.0 | 11.0+0.8 -0.2 | ≤6.50 | 0.25±0.05 | 100 | |

Φ12.0 | 12.0+0.8 -0.2 | ≤7.10 | 0.25±0.05 | 100 | |

Φ13.0 | 13.0+0.8 -0.2 | ≤7.70 | 0.25±0.05 | 100 | |

Φ14.0 | 14.0+0.8 -0.2 | ≤8.30 | 0.25±0.05 | 100 | |

Φ15.0 | 15.0+0.8 -0.2 | ≤8.80 | 0.25±0.05 | 100 | |

Φ16.0 | 16.0+0.8 -0.2 | ≤9.50 | 0.25±0.05 | 100 | |

Size | Supplied I.D. (mm) | After fully recovery (mm) | Standard packing (M/Roll) | ||

Inner diameter | Wall thickness | ||||

Φ2.0 | 2.0+0.8 -0.2 | ≤0.50 | 0.25±0.05 | 200 | |

Φ2.5 | 2.5+0.8 -0.2 | ≤0.60 | 0.25±0.05 | 200 | |

Φ3.0 | 3.0+0.8 -0.2 | ≤0.80 | 0.25±0.05 | 100 | |

Φ4.0 | 4.0+0.8 -0.2 | ≤1.00 | 0.30±0.05 | 100 | |

Φ4.5 | 4.5+0.8 -0.2 | ≤1.20 | 0.30±0.05 | 100 | |

Φ5.0 | 5.0+0.8 -0.2 | ≤1.30 | 0.30±0.05 | 100 | |

Φ6.0 | 6.0+0.8 -0.2 | ≤1.50 | 0.30±0.05 | 100 | |

Φ7.0 | 7.0+0.8 -0.2 | ≤1.80 | 0.30±0.05 | 100 | |

Φ8.0 | 8.0+1.0 -0.2 | ≤2.20 | 0.30±0.05 | 100 | |

Φ9.0 | 9.0+1.0 -0.2 | ≤2.40 | 0.30±0.05 | 100 | |

Φ10.0 | 10.0+1.5 -0.5 | ≤2.70 | 0.30±0.05 | 100 | |

Φ11.0 | 11.0+1.5 -0.5 | ≤2.90 | 0.30±0.05 | 100 | |

Φ12.0 | 12.0+1.5 -0.5 | ≤3.20 | 0.30±0.05 | 100 | |

Note: Special size and packaging can be customized upon request.