Suzhou Volsun Electronics Technology Co., Ltd.

Volsun's Safety Protection Solutions for New Energy Vehichle Industry

In the new energy vehicle industry, Volsun mainly provides three major safety protection solutions, namely, the safety protection solution for new energy vehicle drive motors, the protection solution for new energy vehicle electronic control systems, and the safety protection of new energy vehicle power batteries.

So, what products are needed to implement these solutions?

Let's first take a look at the safety protection solution for new energy vehicle drive motors. According to the protection part and the purpose of protection, this is divided into the wiring harness protection, thermal conductive sealing and bearing protection of the drive motor. We know that motors are divided into water-cooled motors and oil-cooled motors. Therefore, different motors involve the need to use different product solutions.

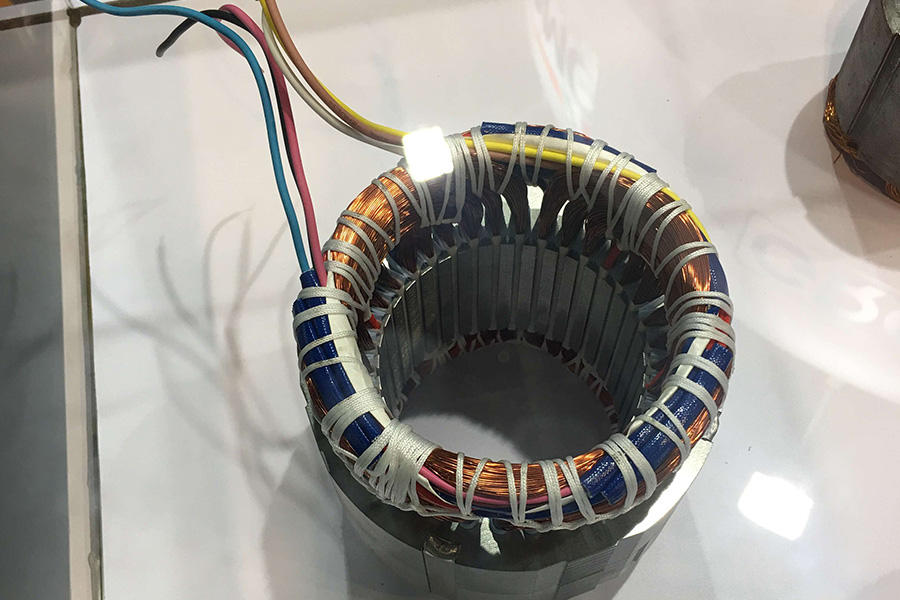

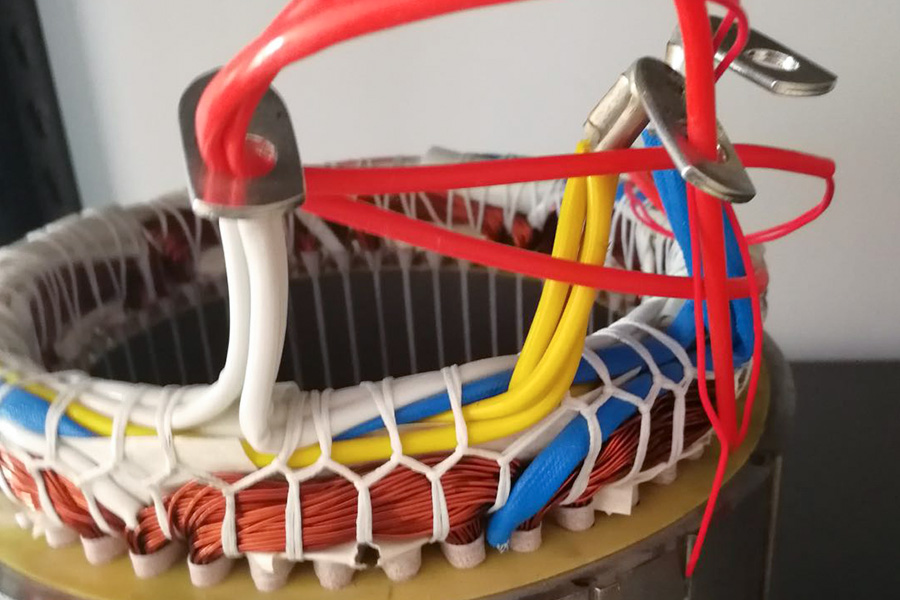

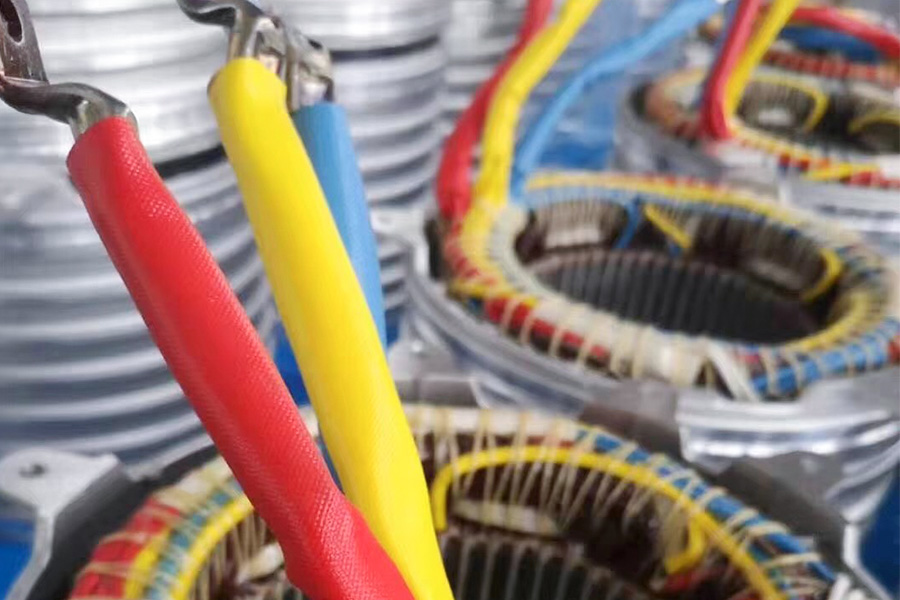

For the protection of water-cooled motors, you can use the silicone rubber glass fiber sleeves, silicone rubber heat shrink tubing and aramid 1414 binding ropes produced by our factory. They all have excellent insulation and high temperature resistance, and have a good protective effect on the motor wiring harness. Particularly worth mentioning is the silicone coated fiberglass sleeve, which approved by UL certificate, and it is one of Volsun's main products. Mainly used for the insulation protection of new energy vehicle drive motors, special vehicles, rail transit and other circuit harnesses. It has high dielectric strength and excellent high temperature aging resistance performance and flame retardant properties.

For the protection of oil-cooled motors, considering that the product needs to have good oil resistance, it is recommended to use our oil-resistant and high-temperature resistant fluororubber heat shrink tubing, and high-temperature resistant and mechanically high PPS braided sleeves and PPS binding ropes.

Our silicone coated fiberglass sleeves, heat shrink tubes and binding ropes are non-toxic and environmentally friendly, and all comply with RoHS and REACH certifications.

When it comes to thermal sealing of motors, we can also provide corresponding product solutions. The main products used are silicone series thermal potting compound, thermal pads, thermal conductive gap filler gel and polyurethane series structural compound with excellent bonding performance. These products have excellent thermal conductivity, low thermal resistance, self-leveling, and the maximum operating temperature can reach 200 degrees. These thermal conductive series products, thermal conductivity, viscosity, hardness and color, etc. can all be customized.

For motor bearing protection, our company has developed and produced a new product, the VS-RD series shaft grounding ring. We know that during the operation of the motor, due to the increase in voltage, overload current will be generated, which will cause electrical corrosion and affect the service life of the motor. Our shaft grounding ring is composed of conductive fibers and metal bodies, which can effectively reduce the potential induction between the bearing and the grounded housing, better solve the problem of electrical corrosion caused by shaft current, and protect the bearing from damage.

Regarding the safety protection of the electric control system of new energy vehicles and the safety protection of power batteries, it is mainly the sealing protection of the shell, as well as the protection of thermal conductive potting, filling and structural bonding of the parts inside the module that need heat dissipation. Using our thermal conductive potting compound, thermal conductive gap filler gel, thermal conductive silicone pad, silicone sealant and structural adhesive, according to the specific application protection parts, using these products in combination can form a perfect solution.

Applications Scenarios

|  |  |

| Fiberglass sleeve application | Fiberglass sleeve application | Fiberglass sleeve application |

|  |  |

| Fiberglass sleeve application | Fiberglass sleeve | Fiberglass sleeve application |