Suzhou Volsun Electronics Technology Co., Ltd.

| Availability: | |

|---|---|

| Quantity: | |

FST6525

Volsun

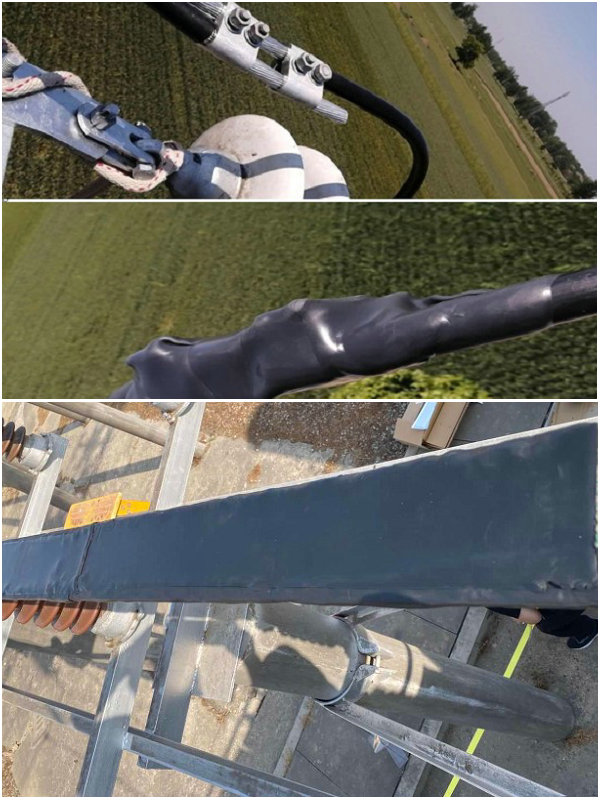

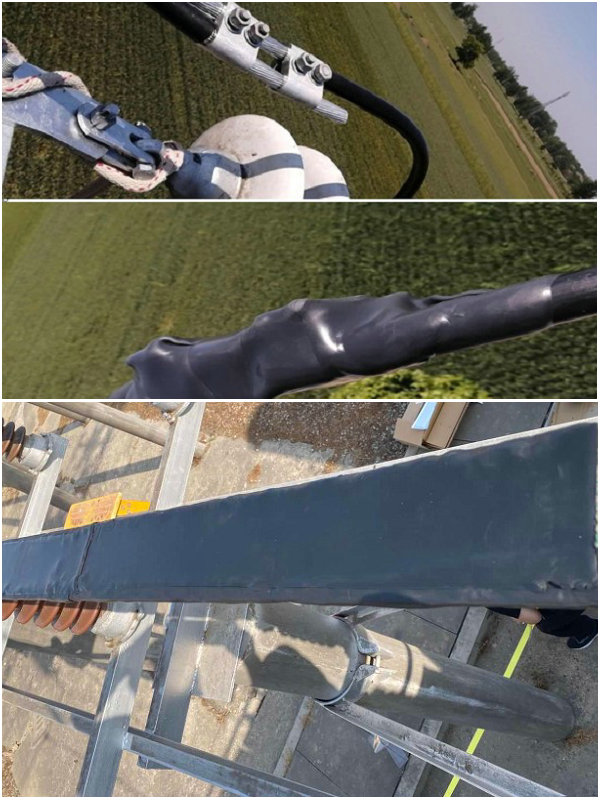

Our self-curing insulation waterproof protection material, designed as a superior alternative to the 3M 525W product. This cutting-edge solution offers exceptional insulation and waterproofing performance, making it ideal for various applications such as insulating and waterproofing irregularly shaped components like overhead line connectors, line clamps, and jumpers in distribution networks. It is also highly effective for insulating exposed metal parts within switch cabinets and providing waterproof protection for equipment in 4G and 5G base station installations, including antennas and splitters.

Our product simplifies the installation process, requiring only the tight wrapping and compression of the material around the designated area. Once exposed to air, the material gradually self-cures, forming a reliable insulation and waterproofing layer. Its straightforward operation makes it suitable for rapid repair tasks, eliminating the need for heating or specialized tools. Furthermore, the material can be easily trimmed and molded on-site to accommodate specific requirements.

Ideal for sealing and insulating overhead wire clamps, reinforcing insulation in areas with inadequate safety clearance, and other similar applications.

Provides insulation protection for exposed metal sections of power conductors.

Suitable for repairing localized insulation on overhead conductors and insulating cable terminal accessories.

Ensures insulation protection for bare metal components within switchgear.

Specifically designed to seal cable entry points in electric cabinet-type installations, particularly for outdoor usage. Also suitable for waterproofing 4G and 5G base station construction equipment, such as unique antennas, splitters, and tower defenses.

Applicable to other power and waterproof applications, including high-speed rail, maritime vessels, and related industries.

Our self-curing insulation waterproof protection material, designed as a superior alternative to the 3M 525W product. This cutting-edge solution offers exceptional insulation and waterproofing performance, making it ideal for various applications such as insulating and waterproofing irregularly shaped components like overhead line connectors, line clamps, and jumpers in distribution networks. It is also highly effective for insulating exposed metal parts within switch cabinets and providing waterproof protection for equipment in 4G and 5G base station installations, including antennas and splitters.

Our product simplifies the installation process, requiring only the tight wrapping and compression of the material around the designated area. Once exposed to air, the material gradually self-cures, forming a reliable insulation and waterproofing layer. Its straightforward operation makes it suitable for rapid repair tasks, eliminating the need for heating or specialized tools. Furthermore, the material can be easily trimmed and molded on-site to accommodate specific requirements.

Ideal for sealing and insulating overhead wire clamps, reinforcing insulation in areas with inadequate safety clearance, and other similar applications.

Provides insulation protection for exposed metal sections of power conductors.

Suitable for repairing localized insulation on overhead conductors and insulating cable terminal accessories.

Ensures insulation protection for bare metal components within switchgear.

Specifically designed to seal cable entry points in electric cabinet-type installations, particularly for outdoor usage. Also suitable for waterproofing 4G and 5G base station construction equipment, such as unique antennas, splitters, and tower defenses.

Applicable to other power and waterproof applications, including high-speed rail, maritime vessels, and related industries.